Maximizing Efficiency and Hygiene in the Food and Beverage Industry with Vacuum Duty Root Blowers: A Comprehensive Guide

In the dynamic landscape of the food and beverage industry, maintaining product quality, ensuring hygiene, and optimizing operational efficiency are paramount. One critical component that significantly contributes to achieving these goals is the Vacuum Duty Root Blower. These blowers play a vital role in various processes, from pneumatic conveying to vacuum packaging, ensuring that operations run smoothly and products meet stringent quality standards.

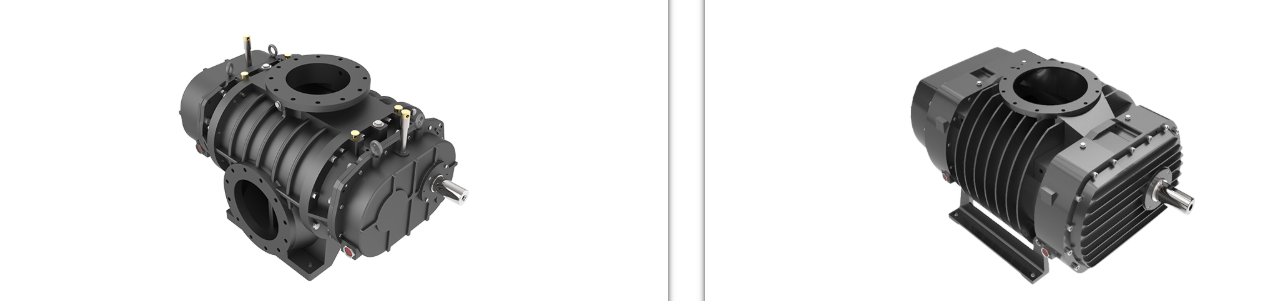

Understanding Vacuum Duty Root Blowers

Vacuum Duty Root Blowers, also known as Positive Displacement Blowers, operate by trapping a fixed amount of air between the lobes and the casing, then displacing it at a steady rate. This mechanism ensures continuous airflow without fluctuations, making them ideal for applications requiring consistent air movement.

Key Features:

- Oil-Free Operation: Ensures that the air delivered is free from contaminants, crucial for food and beverage applications.

- Consistent Airflow: Provides a steady stream of air, essential for processes like pneumatic conveying and vacuum packaging.

- Low Maintenance: Robust construction leads to reduced downtime and maintenance costs.

- Energy Efficiency: Designed to reduce energy consumption, contributing to cost savings.

Applications in the Food and Beverage Industry

- Pneumatic Conveying: In food processing plants, ingredients like flour, sugar, grains, and spices need to be transported efficiently and hygienically. Vacuum Duty Root Blowers facilitate pneumatic conveying systems that move these materials through pipelines using air pressure, minimizing contamination risks and ensuring product integrity.

- Vacuum Packaging: Preserving the freshness and extending the shelf life of food products is critical. Vacuum packaging removes air from the packaging before sealing, inhibiting the growth of aerobic bacteria. Vacuum Duty Root Blowers are integral to this process, providing the necessary vacuum levels efficiently.

- Drying and Cooling: Post-processing steps often require drying or cooling of products. Vacuum Duty Root Blowers supply the necessary airflow for these processes, ensuring that products reach the desired moisture content and temperature levels promptly, which is vital for product quality and safety.

- Fermentation and Aeration: Fermentation processes, such as those used in brewing and dairy production, require precise control of oxygen levels. Vacuum Duty Root Blowers provide controlled aeration, promoting optimal microbial activity and consistent product quality.

- Wastewater Treatment: Food and beverage facilities generate wastewater that must be treated before discharge. Vacuum Duty Root Blowers are used in aeration tanks to supply oxygen, facilitating the breakdown of organic matter by aerobic bacteria, thus ensuring compliance with environmental regulations.

Advantages of Using TMVT's Vacuum Duty Root Blowers

TMVT's commitment to quality and innovation makes their Vacuum Duty Root Blowers a preferred choice in the food and beverage industry.

- Hygienic Design: TMVT's blowers are designed with hygiene in mind, featuring oil-free operation and materials suitable for food-grade applications, thereby minimizing contamination risks.

- Customization: Understanding that different processes have unique requirements, TMVT offers customizable solutions to meet specific operational needs, ensuring optimal performance.

- Energy Efficiency: Their blowers are engineered to consume less energy without compromising performance, leading to cost savings and reduced environmental impact.

- Robust Construction: Built to withstand the demanding environments of food processing plants, TMVT's blowers offer durability and long service life.

- Comprehensive Support: TMVT provides end-to-end support, from selection and installation to maintenance, ensuring that clients receive the best possible service.

Conclusion

Vacuum Duty Root Blowers are indispensable in the food and beverage industry, contributing to efficient, hygienic, and reliable operations. TMVT's range of high-quality blowers offers tailored solutions to meet the diverse needs of this sector. By integrating these blowers into various processes, food and beverage manufacturers can achieve enhanced product quality, operational efficiency, and compliance with hygiene standards.

This comprehensive guide provides a practical and insightful approach to enhancing productivity while ensuring hygienic standards in the food & beverage industry through utilization of vacuum duty root blowers, illustrating their efficacy efficiently without compromising on cleanliness.

This comprehensive guide on harnessing vacuum duty root blowers to maximize efficiency and promote hygiene within the food and beverage industry is an invaluable resource, effectively showcasing how these systems can streamline processes while ensuring safety standards.

This comprehensive guide provides invaluable insights into utilizing vacuum duty root blowers to enhance efficiency and sanitation practices within the food & beverage industry, highlighting how they foster a cleaner production environment while maximizing operational effectiveness.

This guide provides an insightful and extensive analysis on harnessing vacuum duty root blowers to optimize efficiency while maintaining hygiene standards in the food & beverage industry, making it a valuable resource for managers seeking advanced solutions.

This comprehensive guide effectively illustrates how vacuum-duty root blowers can significantly enhance efficiency and maintain hygienic standards in the food and beverage industry, offering valuable insights for improving operational practices.

This comprehensive guide provides insightful strategies on leveraging vacuum duty root blowers for optimal efficiency and hygiene enhancement within the food & beverage industry, ensuring a sanitary yet cost-effective approach to processing.