Preparing Your Team for BRCGS Issue 9 Audit: A Comprehensive Guide to Success

Preparing for a BRCGS Issue 9 audit can turn a potentially stressful event into a smooth and successful review. As the latest food safety and quality standard (launched in 2023), BRCGS Issue 9 requires thorough scrutiny of everything from cleanliness and equipment maintenance to paperwork and company culture. The key to success is preparation, and by following these practical tips, your employees will feel confident and prepared for the audit.

Issue 9 emphasizes a positive food safety culture, where everyone from line workers to managers understands and cares about safe practices. Leadership is crucial in reinforcing good habits, such as walking the floor, answering questions, and praising correct behavior. Encourage open communication so staff can report hazards or suggest improvements. Short daily briefings or safety posters can keep key practices at the forefront of everyone's mind. Recognizing safe work habits also helps make following procedures second nature.

Train and Engage Your Team

Once the right tone is set, focus on clear, hands-on training. Your team should know why each procedure is done, not just what to do. For example, don't just tell operators to "sterilize tools" – explain that this step prevents product contamination. When employees understand the purpose, they'll remember and follow procedures under pressure. Use quick-reference guides, such as checklists or tips posted in break rooms, to reinforce memory. Involve everyone in training, including new hires and all shifts, and hold short refresher meetings to keep the team up to date.

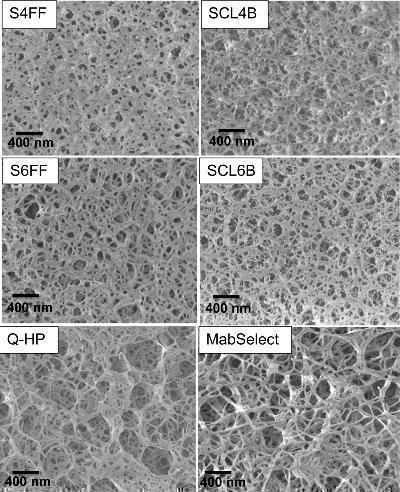

Prepare and Organize BRCGS Issue 9 Documents

Auditors expect documentation for every process. Ensure your BRCGS Issue 9 documents are current, accurate, and well organized. Every policy or procedure should show the latest revision, and every log should be complete and signed. Centralize and label records using a digital system or a clearly marked binder. Organize folders by topic (for example, sanitation, equipment, training) and train staff on where to find each document. This prevents confusion and saves time. Check completeness by running through an audit checklist and verifying every required document is present.

Conduct Internal Audits and Practice Inspections

Regular practice audits help catch issues early. Schedule internal or mock audits so your team knows what to expect. Treat these like the real thing: use a checklist, walk through each area, observe processes in action, and review records. Fix any problems you find so the actual audit is just a confirmation of routine. Assign someone (or hire a consultant) to do a thorough walkthrough and verify that procedures are actually followed on the line. Make it a routine to conduct practice audits regularly (for example, by department or monthly). Ongoing checks build a habit of compliance and prevent last-minute surprises.

Final Steps Before the Audit

Do a final walkthrough to ensure work areas are clean and clutter-free. Confirm that protective clothing (hairnets, gloves, etc.) is stocked and in good condition. Check that all instruments (like thermometers or metal detectors) have up-to-date calibration stickers or logs. Gather everyone and review the audit schedule, explaining who the auditor is and what to expect. Assign a few go-to staff to guide the auditor and retrieve documents as needed. Remind all employees to be polite, honest, and clear in their answers. Encourage the team to view the audit as an opportunity to showcase daily excellence and remind them that being well-prepared means there's nothing to fear. A calm, knowledgeable team makes a very positive impression.

By following these steps – strengthening safety culture, training thoroughly, organizing documents, and practicing – your team will be well prepared for the BRCGS Issue 9 audit. Auditors will see that every employee knows the routine and that safety is part of daily work. A confident, informed team is your best asset on audit day.

This comprehensive guide offers a clear and step-by - laid plan for team members looking to ace their BRCGS Issue 9 audit. With its practical tips, resources lists & invaluable checklists it is truly an indispensable resource kit that has the potential of turning challenges into opportunities."

This comprehensive guide offers practical insights and detailed checks for preparing teams before the BRCGS Issue 9 audit. Its step-by–step approach helps ensure seamless compliance, instilling confidence among both management as well as frontline staff alike."

This comprehensive guide offers a step-by-*eliminate text confusing part*- by *illustrative examples on how to effectively preparet* approach for teams aspiring success in the BRCGS Issue 9 audit, making it an indispensable resource.

This comprehensive guide offers practical tips and insights for effectively preparing a team's readiness before BRCGS Issue 9 audit, ensuring seamless compliance through detailed step-by-step procedures. A must for any organization seeking to excel during the auditing process.

This comprehensive guide offers a step-by--step approach for preparing your team to ace the BRCGS Issue 9 audit, ensuring both compliance and organizational excellence. A must read resource.

This comprehensive guide offers a step-by-.20px by dry.preparation strategy to help teams acing the BRCGS Issue 9 audit, ensuring an efficient and successful process that meets all standards.

This comprehensive guide provides invaluable insights and practical steps for teams looking to ace the BRCGS Issue 9 audit. Its structured approach, end-to Self My Characteristics right clear guidelines on preparing a team ensures readiness at each critical stage.

This comprehensive guide offers an exhaustive overview of how to effectively prepare your team for the BRCGS Issue 9 audit, ensuring compliance with stringent food safety standards. The steps are clear and actionable; a must-read resource before embarking on any certification journey!