在当今数字化时代,Pharma 4.0——工业4.0概念在制药行业的应用,旨在提高生产效率、产品质量和一致性,该领域面临诸多挑战,包括人工智能、材料追溯性、优化、过程控制、网络安全以及数据管理等,这些挑战源于制药行业的复杂性和高要求。

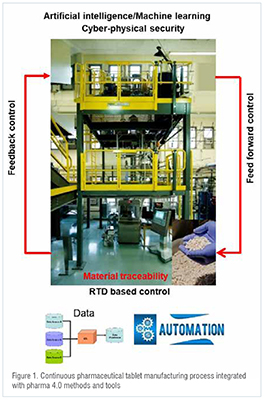

为了应对这些挑战,制药行业正在积极引入先进的工业4.0概念和技术,一个连续的直接压片胶囊制药生产线,位于美国 Rutgers 大学的 C-SOPS,就是一个成功的实例,这个垂直设计的生产线利用重力材料流动原理,无需使用传统的压片机带,从而实现了直接压片线的三维结构。

这个连续制药生产线的工艺流程包括多个关键环节,原料和辅料的输送通过顶部的高层次设备进行,经过混合和初步加工后,进入下一阶段的压片机,产品通过一个中间的压片通道进入最终包装阶段,整个过程中,还配备了先进的材料追溯系统,确保了产品生产过程中的可追溯性。

在开发工业4.0概念方面,该连续制药生产线的七个关键领域得到了深入研究和应用,其中包括人工智能(AI)/机器学习(ML)、建模、优化、先进控制、材料追溯性、网络安全和数据科学等,这些技术的应用旨在提高制药过程的效率和准确性,从而提升产品质量和生产一致性。

AI/ML算法在制药行业中展现出巨大的潜力,这些算法能够精确预测制药过程的响应,为高效制造高质量产品提供了新的可能性,还有一些其他方法和技术也被应用于该领域,例如建模和优化技术,这些技术可以帮助制药企业更好地理解生产过程,优化工艺参数,从而提高生产效率和质量。

在材料追溯性方面,该生产线采用了先进的系统来确保产品生产过程中的可追溯性,这包括材料流动的监控、产品的物理特性检测以及产品的质量检测等环节,通过这些环节,可以确保产品的来源可查、去向可追,从而提高了产品的透明度和可信度。

网络安全在该领域也扮演着重要角色,随着制药行业的不断发展,网络安全问题也日益突出,该生产线配备了先进的网络安全系统,以确保数据传输和存储的安全性。

Pharma 4.0在制药行业的应用是一个充满挑战和机遇的过程,通过引入先进的工业4.0概念和技术,制药企业可以提高生产效率和质量,降低生产成本和风险,这也需要企业在应用过程中不断探索和创新,以适应不断变化的市场需求和技术趋势。

Pharma 4.0: Advanced Continuous Pharmaceutical Tablet Manufacturing empowers the industry to streamline operations, enhance production efficiency and quality control through smart automation – a revolution that integrates precision with speed for tomorrow’s medicine manufacturing needs.

Pharma 4.0 represents a pivotal shift in the pharmaceutical industry towards highly advanced and continuous tablet manufacturing, streamlining operations while enhancing product quality through integrated digital solutions.

Pharma 4.0's embrace of advanced continuous pharmaceutical tablet manufacturing revolutionizes the industry, enabling unparalleled efficiency and precise production at scale while ensuring drug quality through real-time监控.

Pharma 4.0: The breakthrough in Advanced Continuous Pharmaceutical Tablet Manufacturing enables a level of precision, efficiency and scalability unparalleled to date for the pharmaceutical industry's production chain.

Pharma 4.0 offers a visionary approach to continuous pharmaceutical tablet manufacturing, poised at the forefront of innovations in the pharmaceutical industry with its emphasis on automation and data-driven decision making.

Pharma 4.0 offers a promising vision for the future of continuous pharmaceutical tablet manufacturing, transforming industry processes through advanced automation and digitalization to ensure faster production with higher quality standards.

Pharma 4.0: Advanced Continuous Pharmaceutical Tablet Manufacturing presents a revolutionary approach that fundamentally reshapes the pharmaceutical industry's production paradigm, driving efficiency and quality advancements through advanced automation techniques.

Pharma 4.0: Advanced Continuous Pharmaceutical Tablet Manufacturing' introduces promising prospects for the pharmaceutical industry by enhancing efficiency, precision and real-time monitoring capabilities in tablet production process.

Pharma 4.0: Advanced Continuous Pharmaceutical Tablet Manufacturing presents a groundbreaking approach that integrates next-generation automation, data analytics and advanced robotics to improve efficacy while reducing production time in the pharmaceutical industry.

Pharma 4.0: Advanced Continuous Pharmaceutical Tablet Manufacturing represents a paradigm shift in the pharmaceutical industry, leveraging automation and digitalization to enhance efficiency while maintaining stringent quality standards.

Continuous manufacturing lines in Pharma 4.0 demonstrate a remarkable integration of advanced technologies, fostering efficient and precise production processes while adhering to strict regulatory standards for pharmaceuticals.

The application of continuous pharmaceutical production lines in Pharma 4.0 demonstrates a remarkable progression towards automation, efficiency and precision within the industry.

The example of a continuous pharmaceutical production line in Pharma 4.0 and its application exemplifies the cutting-edge automation, precision, efficiency gains while ensuring safety standards – an innovative step towards optimized drug manufacturing processes.

![Truck Axle Market [2029] Key Trends and Strategies for Expansion](https://antiochtenn.com/zb_users/upload/2025/08/20250831205217175664473759450.jpg)

![Fibrin Sealant Market Advancements and Business Opportunities [2028]](https://antiochtenn.com/zb_users/upload/2025/08/20250831183354175663643499373.jpg)