In today’s digital-first event and display world, LED video wall panels have become synonymous with high-impact visual storytelling. From electrifying concert stages to immersive corporate presentations and sprawling digital signage in public spaces, these panels have revolutionized how we communicate with large audiences. But behind the seamless visuals and vibrant color reproduction lies an intricate ecosystem of components, engineering, and electronics.

In this comprehensive technical guide, we delve deep into the inner workings of LED video wall panels. Whether you’re an event production manager, AV engineer, or tech-savvy venue owner, understanding how these systems function can help you make smarter investment, installation, and operational decisions.

What Are LED Video Wall Panels?

At a fundamental level, LED video wall panels are modular display units made up of thousands—often millions—of light-emitting diodes (LEDs) arranged in a grid pattern. When combined together, these panels create a seamless digital screen capable of displaying dynamic content in a variety of environments and resolutions.

Types of LED Video Wall Panels

Indoor Panels: Optimized for close viewing, indoor LED panels typically have tighter pixel pitches (e.g., P1.9, P2.5), lower brightness, and lightweight enclosures.

Outdoor Panels: Designed to withstand harsh weather, these panels are rated IP65 or higher and come with higher brightness levels (5000–8000+ nits).

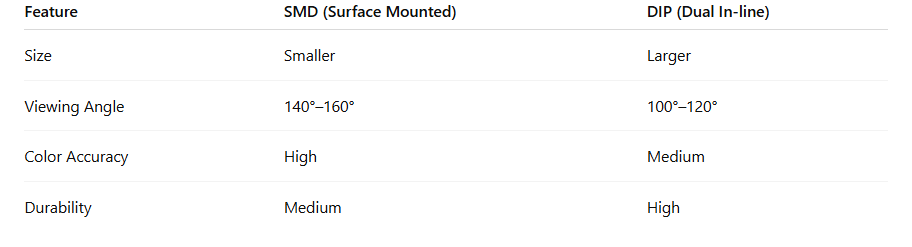

SMD vs. DIP LEDs:

SMD (Surface Mounted Diode): More common today, offering better color blending and viewing angles.

DIP (Dual In-line Package): Older technology, still used in high-brightness applications but with limited angles and higher pixel pitch.

Where Are They Used?

Concerts and music festivals

Corporate AV presentations

Broadcast backdrops

Sports stadiums

Control rooms and command centers

Retail digital signage

Understanding the key parts that make up these panels is the first step in grasping how they work.

Core Components of LED Video Wall Panels

Each LED video wall panel is a complex system comprised of several essential components working together to deliver the final image.

A. LED Modules and Pixel Technology

LED modules are the building blocks of the panel. Each module consists of individual RGB (Red, Green, Blue) LEDs that form pixels.

SMD vs DIP Breakdown

What Is Pixel Pitch?

Pixel pitch (e.g., P2.5, P3.9) measures the distance between two adjacent LED pixels (in mm). A smaller pitch means higher resolution.

P1.9 = Higher resolution, ideal for indoor short-distance viewing

P6.0 = Lower resolution, suited for outdoor long-distance viewing

B. Cabinet and Panel Structure

Each LED panel is housed in a cabinet that provides structural support and protection.

Key Features:

Material: Die-cast aluminum or steel

Weight: Lightweight for easy stacking or hanging

Mounting: Fast locks and alignment pins for seamless display

Weatherproofing: For outdoor models (IP65-rated)

Access: Front or rear maintenance options

These cabinets allow for easy module replacement and structural integrity during live installations.

C. Power Supply System

Every panel includes a power supply unit (PSU) that converts incoming AC power (typically 110V–240V) to DC voltages required by the LED modules.

Common voltages: 5V DC or 3.3V DC

Redundancy: High-end systems may feature dual power inputs

Cooling: May include passive or active cooling systems

PSUs also include circuit protection for overcurrent, voltage spikes, and short circuits.

LED Signal Processing and Control Systems

The magic of LED walls lies not just in their physical components, but in the sophisticated signal control systems that feed content to each pixel.

A. Signal Flow: Sending and Receiving

The data flow begins with a media source, such as a computer or video mixer, and follows this pathway:

Media Input Device (e.g., laptop, video switcher)

Sending Card – Encodes video signal and transmits data over Ethernet or fiber

Receiving Card – Decodes signal and maps pixels on each panel

Driver ICs – Convert data into instructions for LEDs to turn ON/OFF at specific brightness levels

Common Technologies:

Novastar

Colorlight

Linsn

Brompton Technology

B. Video Processors

These are responsible for:

Scaling video to panel resolution

Splitting content across multiple panels

Edge correction for seamless visuals

Color calibration

Frame synchronization

A processor ensures real-time, high-fidelity video delivery even when content is dynamic or mixed-signal (HDMI, SDI, DVI).

Example:

For a P3.9 1920x1080 wall, the video processor might rescale a 4K input while retaining color accuracy across all panels.

Synchronization and Refresh Rate

To prevent flickering or ghosting during camera recording or live playback, refresh rates must be high.

Standard Refresh Rate: 1920 Hz

Professional Grade: 3840 Hz or higher

Higher refresh rates allow:

Smoother motion rendering

Better performance under stage lighting

Syncing with timecode for music/video coordination

LED drivers and controllers must be configured to maintain frame sync across all panels in a wall.

Cooling, Maintenance, and Heat Management

LEDs and power components generate heat, especially under outdoor sun exposure or 24/7 usage. Thermal regulation is essential to avoid:

Dimming

Color shifting

Component burnout

Cooling Methods:

Passive cooling: Uses metal fins, no moving parts

Active cooling: Includes fans or heat sinks

Intelligent monitoring: Alerts for overheating or voltage errors

Well-ventilated designs extend the life of both the LEDs and the PSU, and many panels are now equipped with thermistors and temperature sensors.

Common Technologies Used in LED Wall Panels

1. Smart Calibration

Auto-adjusts brightness and color balance across all modules, ensuring uniformity even after module swaps.

2. HDR Support

High Dynamic Range enhances contrast and color depth, useful for cinematic or branded visual storytelling.

3. Remote Diagnostics

Cloud-based systems monitor panel health, power status, and signal quality. Technicians can troubleshoot remotely.

4. Modular Redundancy

In high-stakes events, backup signal routes and power systems are integrated to prevent downtime.

5. Wireless or App-Based Controls

Technicians can operate displays via mobile apps for convenience during live shows.

Case Study: Technical Setup for a 20ft x 10ft Concert Stage LED Wall

Project Goals:

Resolution: 1920 x 1080 full HD

Brightness: 5000 nits for outdoor sunlight

Panel Type: P3.9 outdoor SMD

Hardware Used:

50 x P3.9 panels (500mm x 500mm)

Novastar VX1000 processor

Dual redundant power supplies

Signal routed via Cat6 Ethernet + Fiber backbone

Edge-blending software for seamless image stitching

Outcome:

Live synced content with 3840 Hz refresh rate

Remote control during performance

Minimal latency (~2ms)

This setup is typical for mid-sized concerts or festivals with high visual fidelity requirements.

FAQs

1. What is pixel pitch and how does it affect resolution?

Pixel pitch is the distance (in mm) between two LEDs. Smaller pitch = higher resolution. For close viewing, use P1.5–P2.5; for long-distance, P5–P10.

2. What’s the difference between sending and receiving cards?

Sending cards take video input and convert it into data signals. Receiving cards decode the signal and control LEDs on specific panels.

3. Can indoor panels be used outdoors?

Not recommended. Indoor panels lack waterproofing (no IP65 rating) and can overheat or short-circuit outdoors.

4. What causes LED wall flickering?

Common reasons include poor refresh rate settings, incompatible processors, or faulty driver ICs.

5. How long do LED video wall panels last?

High-quality panels last between 80,000–100,000 hours (~8–10 years), depending on usage and maintenance.

6. What is the role of the video processor?

It scales, splits, and calibrates the video input, maintaining color and resolution across the LED wall.

7. Do I need special software for control?

Yes. Most systems use proprietary software (e.g., NovaLCT, Colorlight LED Studio) for setup, diagnostics, and calibration.

Conclusion

LED video wall panels are marvels of modern engineering—blending electrical design, software control, optical technology, and physical durability. From high-density indoor displays to rugged outdoor setups, each panel functions as part of a highly coordinated system of LEDs, controllers, signal processors, and power components.

Understanding how these systems work enables event professionals, AV technicians, and business owners to make informed decisions regarding equipment selection, troubleshooting, and performance optimization. As display technology continues to evolve, keeping pace with innovations like smart calibration, cloud diagnostics, and ultra-fine pixel pitches will be key to delivering world-class visual experiences.

This in-depth technical overview of how LED video wall panels operate presents a comprehensive and concise explanation, making it an excellent resource for understanding the intricate workings behind these statewide visual displays.

Excellent technical overview of how LED video wall panels operate, providing valuable insights into their underlying technology and operations for professionals in the field.

LED video wall panels, with their remarkable versatility and superior image quality due to advanced color rendering capabilities enabled by precise pixel control technology running in the background of each panel.

This article provides an insightful and comprehensive technical overview of how LED video wall panels function, exploring the intricate interplay between their components such as microprocessors for signal processing.

The technical explanation of how LED video wall panels function in the piece How LED Video Wall Panels Work: A Technical Overview, provides an insightful and comprehensive understanding for those interested in multimedia display technology.

This comprehensive guide provides an insightful technical overview of how LED video wall panels function, effectively unraveling the intricate workings and applications in a readily understandable manner for both professionals and enthusiasts alike.

The comprehensive exploration of how LED video wall panels function in the article How they Work: A Technical Overview provides a helpful foundational understanding for anyone diving deep into visual display technology, clearly outlining its components and mechanisms with technical precision.